Maintenance is much easier when you know the exact condition of your equipment. One common metric, total running hours, is a rough estimate. But running hours won’t give you the details you need for a more itemized maintenance plan.

Konecranes TRUCONNECT® improves your efficiency by enabling you to monitor the condition of every key function and component of your lift trucks in near real-time.

Some practical examples:

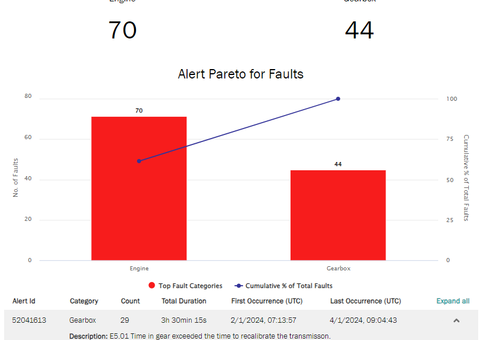

Your gearbox

A properly functioning gearbox is essential for maximizing the safety and optimization of your lift truck assets.

If a fault develops inside the gearbox, it could be a sign that parts are wearing or the transmission needs recalibration. A fault alert informs technicians that a service is needed.

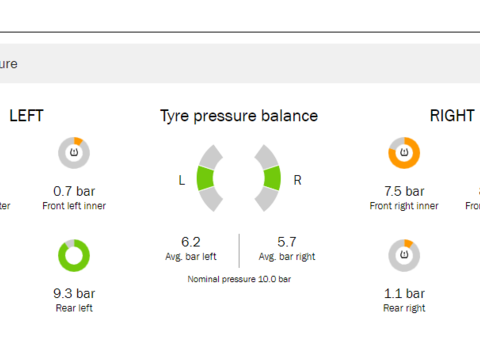

Your tire pressure

Correct tire pressure improves safety by reducing the risk of accidents, helps cut fuel consumption and extends tire lifetime.

If the pressure moves outside of preset limits, tire pressure monitoring tells drivers and technicians to correct tire pressure as soon as possible

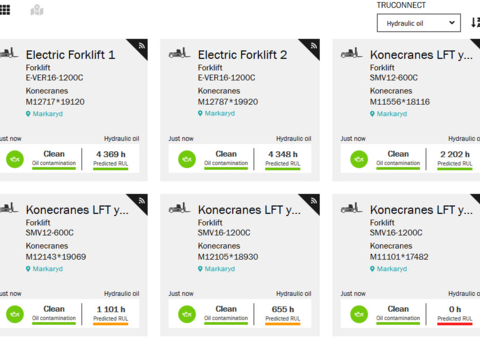

Your oil

Hydraulic oil is costly, so changing it only when really needed can dramatically reduce maintenance costs, increase uptime and ultimately reduce environmental harm.

Condition monitoring sensors collect data on variables such as particles, water content and temperature to predict the remaining useful lifetime of the hydraulic oil.

SAFE FROM THE VERY BEGINNING

Security by design

Secure software development practices ensure security risks are considered in each phase of the software development lifecycle.

This helps developers to build highly secure applications and ensure that security risks and possible vulnerabilities are captured in the development, and not in the production.