More and more of our customers are using yourKONECRANES.com, the Konecranes Digital Experience Platform, which offers an ever-expanding range of digital services, applications and solutions. The platform gives them access to all they need to know about their Smart Connected Lift Trucks, from documentation and inspection reports to maintenance programs and remote monitoring with TRUCONNECT®, a suite of remote service products that help them to optimize their lift truck operations. The most advanced package, TRUCONNECT® Premium+, brings equipment servicing to the next level with condition-based maintenance.

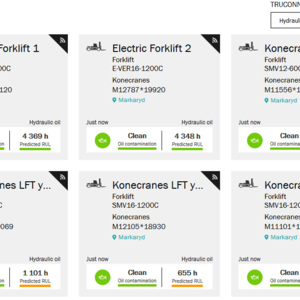

Some Konecranes customers are already using TRUCONNECT Basic. Linked to their lift trucks, it gives them operation and usage data, condition monitoring and alert notifications, fleet productivity optimizations, data-on-demand reporting and Work Zone for location-based services including geofencing. Or they might have upgraded to TRUCONNECT Premium, which has all these features plus tire pressure and shock monitoring. The top level is TRUCONNECT Premium+, which includes all that, and adds oil contamination and condition monitoring for hydraulic oil cleanliness (as per ISO 4406) and water saturation level. It also verifies the oil quality and ageing, estimating its remaining useful lifetime.

“Our digital solutions have been a big hit with our customers,” says Bertrand Marion, Director, Business Development and Digitalization at Konecranes Lift Trucks. “You can’t overstate the benefit of having your assets connected to monitor, analyze, understand & optimize with TRUCONNECT reports on yourKONECRANES. Oil condition monitoring is the latest major addition that you really need to have. Hydraulic oil is a costly resource and harmful to the environment, so changing it only when needed can dramatically reduce maintenance costs and ultimately increase uptime, benefits that grow with the size of your fleet. And you can do it with TRUCONNECT Premium+.”

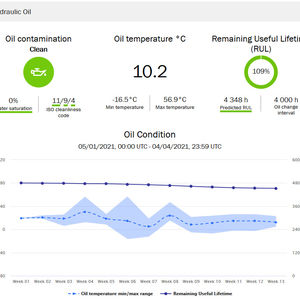

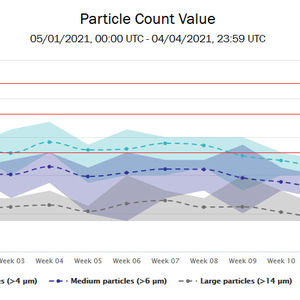

In TRUCONNECT® Premium+, oil monitoring works like this. Sensors check the oil temperature, because a higher temperature speeds up aging and oxidation, degrading of the quality of the oil. An algorithm embedded with Artificial Intelligence (AI) and Machine Learning (ML) combines temperature and other oil parameters changes (such as operating hours, relative permittivity, conductivity, and relative humidity) to continuously predict the remaining useful lifetime of the hydraulic oil as the lift trucks are being used. Sensors also measure particles and water content, as the contamination of hydraulic oil can cause many problems in hydraulic systems, such as filter blockages, accelerated wearing of components, corrosion of metal surfaces, formation of rust and chemical compounds, viscosity variance, and so on. All of this data is available in TRUCONNECT reports at yourKONECRANES.com through color-coded KPIs using a traffic light system. Without the need for oil sample analysis, users can see at a glance whether the oil can still be used (green), observation is required (orange) or it needs to be replaced (red). With consistent green indicators, the same oil can still be used, so service intervals can be extended and oil costs will be reduced. In addition, a decreased need for oil means less time and resources spent on the safe disposal of waste oil and a lower overall environmental impact. Besides the KPIs, data from the sensors is also available in both raw numbers and graphs for a more detailed analysis of the condition of the oil.

If TRUCONNECT Premium+ is not part of a lift truck order, it’s easy to install through our Lifetime Advantage upgrades, as every Konecranes lift truck has been prepared before it leaves the factory. All customers need to do is have the sensors installed on their trucks, then subscribe to the oil condition and contamination monitoring service, and once the lift trucks control system software has been updated remotely, it all appears automatically on the yourKONECRANES.com customer portal. The colored KPIs provide a handy tool for immediate action and a preview of the situation if more in-depth analysis is needed.

“At Konecranes, we understand our customers’ drive for growth, sustainability and tangible business results,” says Andreas Falk, Senior Vice President, Konecranes Lift Trucks. “Providing access to as much information as possible with TRUCONNECT Premium+ will further empower businesses as they move towards a data-driven business.”

The introduction of oil monitoring in TRUCONNECT Premium+ is another step towards full condition-based maintenance and the best way to take care of Konecranes lift trucks. With the full set of data on their equipment, customers can plan ahead easily, save more money, and optimize their operations for safety, productivity and profit for many years to come.